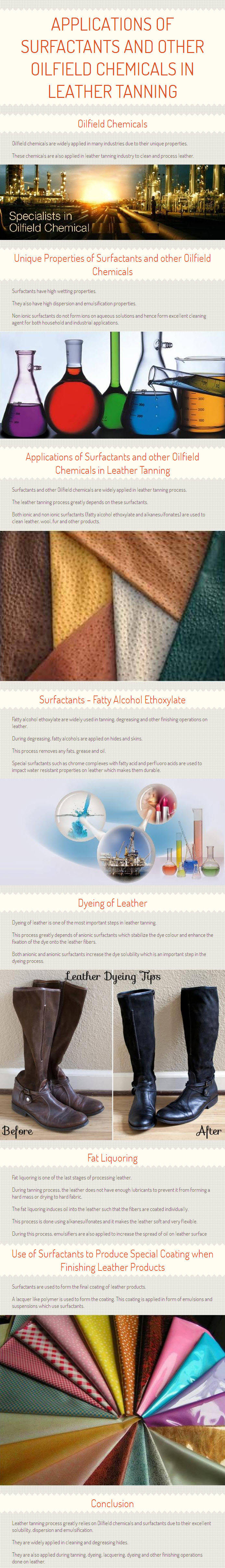

Applications of Surfactants and Other Oilfield Chemicals in Leather Tanning [INFOGRAPH]

Surfactants have high wetting properties. They also have high dispersion and emulsification properties. Non ionic surfactants do not form ions on aqueous solutions and hence form excellent cleaning agent for both household and industrial applications. Due to their emulsification properties, surfactants promote mixing of immiscible liquids and are not affected by hard water and other insoluble properties of liquids.

Leathers and fur are mostly treated with surfactants and other oil field chemicals in order to produce a protective coating on the skin of the fibers. Surfactants also prevent the furs and hide fibers from sticking together. Surfactants increase the tensile strength of the leather products making it more durable and attractive. Surfactants are used to form the final coating of leather products. A lacquer like polymer is used to form the coating. This coating is applied in form of emulsions and suspensions which use surfactants. More details about surfactants visit at http://www.rimpro-india.com/surfactant.html.

Leather tanning process greatly relies on oil field chemicals and surfactants due to their excellent solubility, dispersion and emulsification. They are widely applied in cleaning and degreasing hides. They are also applied during tanning, dyeing, lacquering, dyeing and other finishing operations done on leather.

This infograph has been posted by

Govind Patel.